Product Introduction

Powder Compacting Presses, Sizing Presses

A powder Compacting press feeds blended raw powder—created by mixing powders of various materials—into a mold and compacts it under pressure.

This process minimizes machining requirements and enables the efficient production of high-performance, complex-shaped components.

In particular, our specialty hydraulic molding presses can be customized to meet each customer’s specific needs.

For example, they can maintain high pressure at elevated temperatures on the raw powder, or perform repeated pressurizing and depressurizing cycles to remove trapped air during molding.

Powder Compacting Presses, Sizing Presses

- Powder Compacting Presses (Cold, Warm, Hot)

- Hydraulic Servo-Controlled (CNC) Powder Compacting Press

- Magnetic Field Compacting Presses (Vertical: Parallel Field, Horizontal: Perpendicular Field, Radial Field)

- Multi-Stage Forming Press

- Multi-Layer Compacting Press

- Atmosphere-Controlled Powder Compacting Press

- Sizing Press

Examples of Applications for Powder Molding

Iron-Based, Copper-Based, Resin-Based, Magnetic Materials (Hard & Soft), Friction Materials, Abrasives, Cemented Carbide, Ceramics, Carbon, Battery Materials, Pyrotechnic Products, etc.

-

200 kN Powder Compacting Press with Automatic Powder Feeding System

-

500 kN Powder Compacting Press

-

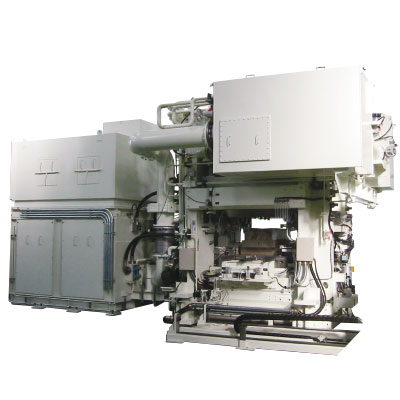

25 MN Powder Compacting Press

Hot Forming Press

Hot forming presses are widely used not only for plastic forming at warm and hot temperatures.

They are also applied to a wide range of materials, including various resins, grinding wheels, electronic components, brake parts, rubber, and wood-based materials.

In particular, our energy-saving hot forming presses significantly reduce power consumption even during

long periods of pressure holding, while maintaining high-precision pressure control throughout the holding process.

In addition, our presses ensure safe operation by automatically transferring heated molds outside the machine.

They can also be equipped with bumping actions to vent gases generated under high-temperature conditions,

as well as vacuum evacuation of the molding chamber and other special specifications, offering exceptional flexibility to meet diverse requirements.

Hot Forming Presses

- Heated Platen Press

- Hot Straightening Press

- CFRP, FRP, and PTFE Molding Presses

- Wood-Based Material Molding Press

- Abrasive and Friction Material Molding Press

- Hot Sizing Press

- Quenching (Hardening, Die Quenching / Press Quenching) and Tempering (Annealing, Press Tempering) Presses

-

600 kN Hot Forming Press

-

6000 kN Wood-Based Material Hot Forming Press

-

8000 kN Quenching Press

Forging Presses and Coining Presses

In recent years, as demand for high-mix, low-volume production continues to grow, cold forging has been attracting increasing attention for its ability to produce only the required quantity efficiently without the need for heating.

In particular, our compact forging presses are increasingly being installed in-line with machining equipment, enabling seamless production.

They eliminate forging scale, deliver superior surface quality, are environmentally friendly, and ensure high-precision component manufacturing.

Cold forging tends to generate highly concentrated loads, but our high-rigidity frames help ensure the production of high-quality components.

Meanwhile, in hot forging, the contact time between the die and the workpiece significantly affects the die’s service life, which is why mechanical presses are commonly used.

However, our hydraulic forging presses take advantage of the unique characteristics of hydraulics, enabling complex processing while keeping the dies clamped under pressure.

Forging Presses and Coining Presses

- Cold Forging Press

- Warm Forging Press

- Hot Forging Press

- Double-Action Forging Press

- Coining Press

-

30,000 kN Aluminum Hot Forging Press

Other Presses

General-Purpose Sheet Metal Forming Press

- Straight-Side Press

- Column-Type Press

- C-Frame Press

- Moving-Ram Straightening Press

- Blanking Press

- Energy-Saving High-Speed Press

- Compact Ultra-High-Pressure Press

-

300 kN Bending Press

-

1000 kN Punching Press

-

1000 kN C-Frame Press

-

1500 kN Caulking Press

-

15,000 kN Moving-Ram Straightening Press

-

1000 kN Compact Press with Casters

Other, Dedicated, and Special-Purpose Machines

- Extrusion Press

- Bulge Forming Press (Hydroforming / Rubber)

- Press-Fitting Machine

- Tilting Press

- Vertical & Horizontal Press

-

70 kN Horizontal Extrusion Press

-

1500 kN Extrusion Press with Glove Box

-

3000 kN Bulge Forming Press

-

1500 kN Tilting Press

-

Brush Assembly Machine

-

300 kN Battery Safety Testing Machine

Cassette Die Set (Tool Set)

- General Cassette Die Set

- Cassette Die Set for Powder Compaction

- Cassette Die Set for Multi-Level Powder Compaction

- Cassette Die Set for Warm & Hot Powder Compaction

- Hydraulic Unit for Various Cassette Die Sets (for Processing, Cushioning, Sealing, etc.)

-

Cassette Die Set for Helical Gear Powder Compacting

-

Cassette Die Set for High-Temperature Powder Compaction

Tool Changeover Device

- Tool Changeover Device (QDC, Automatic / Manual, with Preheating)

- Tool Changeover Cart

- Mold Simulation System

-

Quick Die Changer (QDC)

Press Peripheral Equipment and Other Various Devices

- Mold Flipping Device

- Powder Feeding Device

- Workpiece Feeding and Removal Device

- Phase Alignment and Detection Device

- Handling (Material Handling) Equipment and Transfer Device

- Alignment (Palletizing) Device and Pallet Changer Device

- Glove Box

- Various Assembly, Labor-Saving and Manpower-Saving Devices

- Various Equipment for Experimentation, Testing, Research & Development, and Evaluation

-

Articulated Robot

-

Automatic Conveyor Line

-

Palletizing Equipment

Hydraulic Units, Hydraulic Cylinders, and Steel-Fabricated / Machined Components

- Custom-Made Hydraulic Unit

- Custom-Made Large Hydraulic Cylinders (Ram Type / Piston Type / Double-Rod / Double-Acting, etc.)

- Press Frames and Bolsters

- Hot Plate (Heated Platen) for Press Installation

- Steel-Fabricated & Machined Components